Functional Characteristics:

1. Automatic online design, reduce the cost of manual loading and unloading.

2. Online 1.2 m segment mounting mode to improve the compatibility of online patch machine.

3. Z-axis 10 cameras fly snap at the same time to further optimize the mounting mode and response speed of the device

4. Circuit control system, fully integrated mode

5. Small-spacing pattern of the head module

6. The Y-axis double-motor double-wire rod drive mode further improves the running speed and stability of the machine, and increases the service life of the machine, so that the machine can run more easily.

Applied Range:

1.2 meters lamp board, bulb lamp DOB, downlight, spotlight, suction light, guardrail pipe, LED drive power supply, linear light, soft light belt and 0402 above all electronic materials

Technical Parameter |

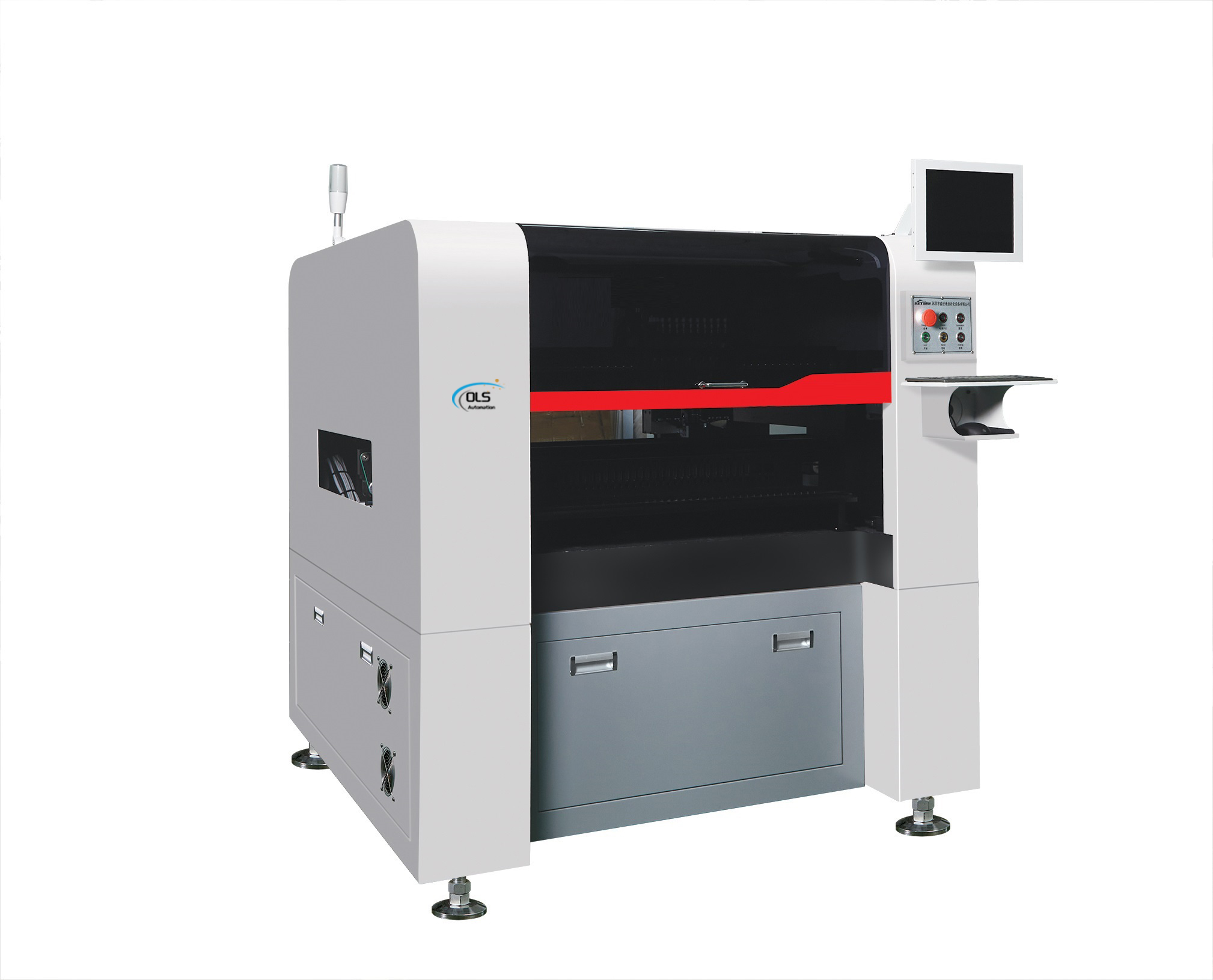

unit type | OLS-F10A (integral camera) |

Maximum circuit board area | 600mm * 380mm (1200mm * 400mm) |

Maximum range of movement | X-axis 650mm, Y-axis 450mm |

Mount element height | 12mm |

Maximum patch speed | 55000 CPH (with suck and stick) |

Average patch speed | 20000-50000CPH |

positioning accuracy | +-0.05MM |

location mode | MARK point camera + 10 group snap camera |

source | 220V, 50Hz, 3KW |

control method | Research and control of industrial computer + sports card |

compressed air | 0.55MPA |

mean power | 2200W |

Feed the device | Electric Feida + pallet feeding (optional) |

scope of application | From the 0402 microchip to the 14mm large elements |

Number of available feeders | 36 (customized bilateral 70 material stations) |

Use the motor | AC servo motor |

Paste head | 10 Head |

Component Angle | 0-360 Any angle, synchronous rotation in motion |

X/Y running mode | A new generation of linear interpolation linkage independent development software |

operating system | WINDOWS 7 |

Programming method | Fully automatic visual camera positioning and programming |

Feed fly da | motor-driven |

Product weight | 1500KG |

Appearance size | L1330MM*W1400MM*H1450MM |